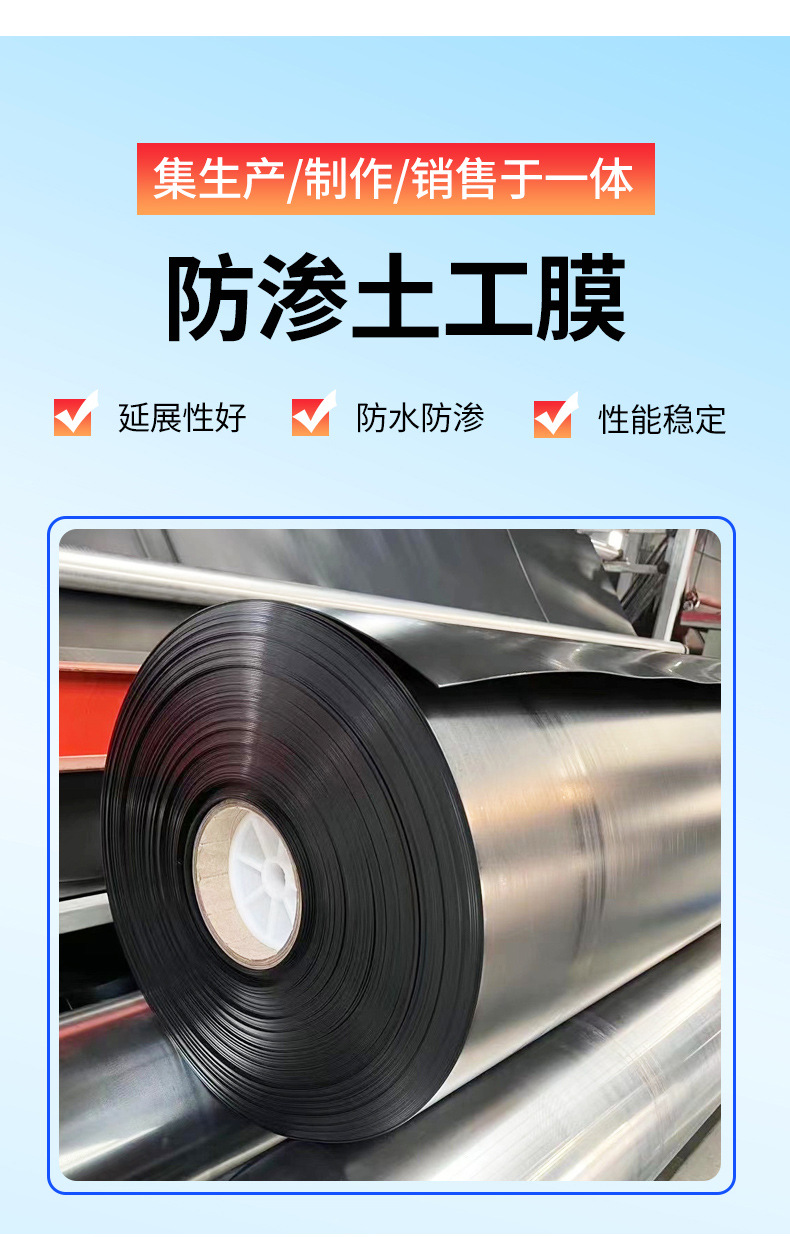

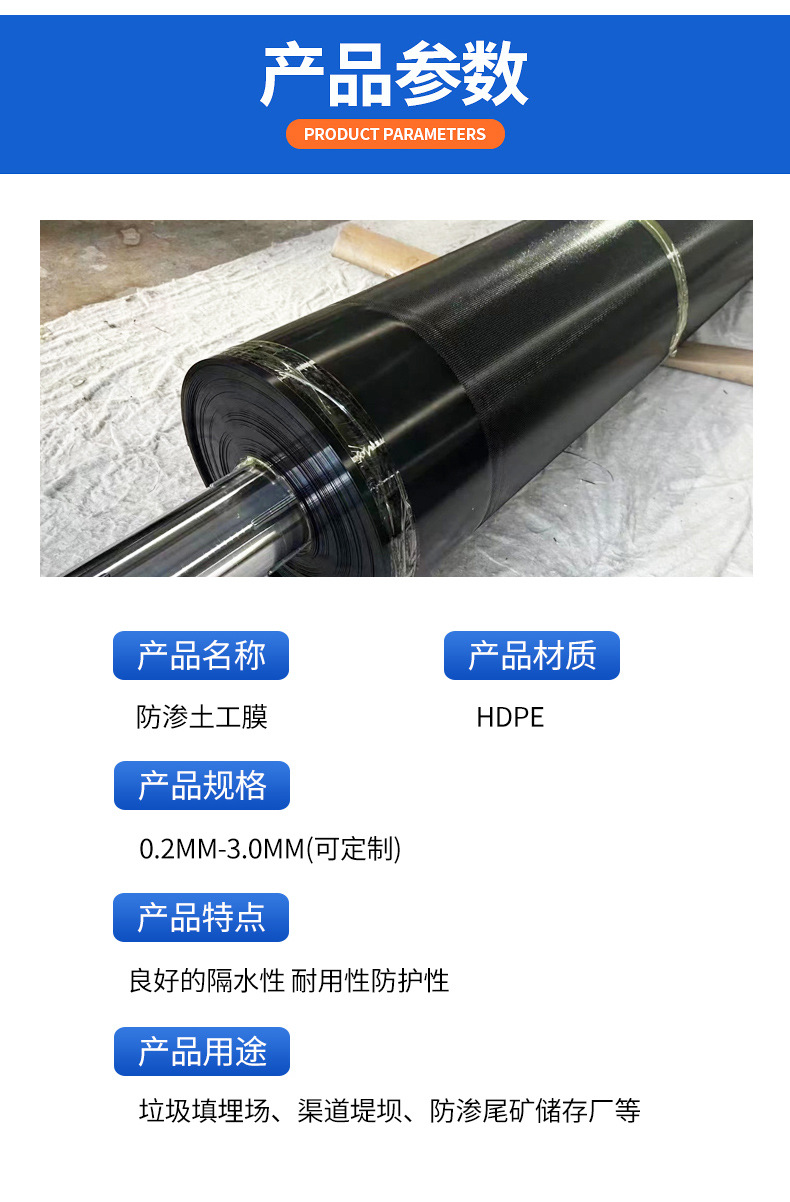

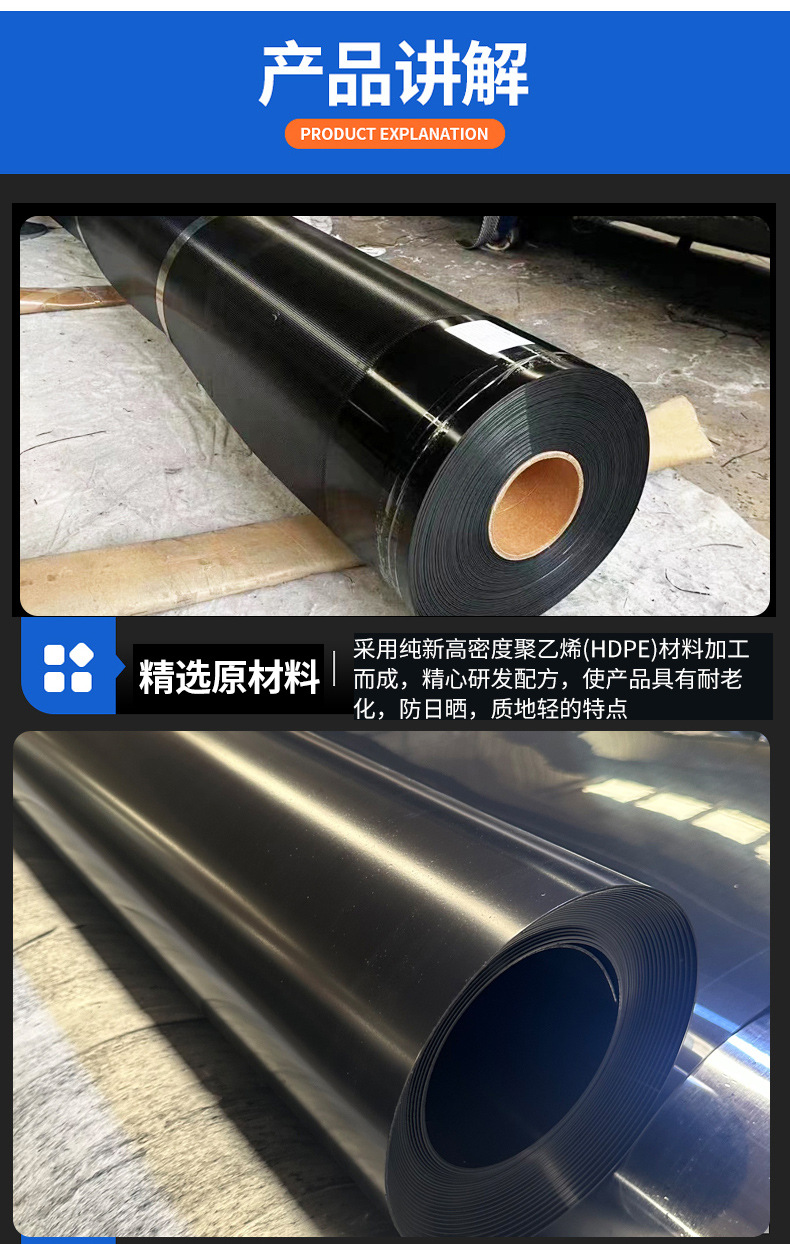

Anti-seepage geomembrane商品描述

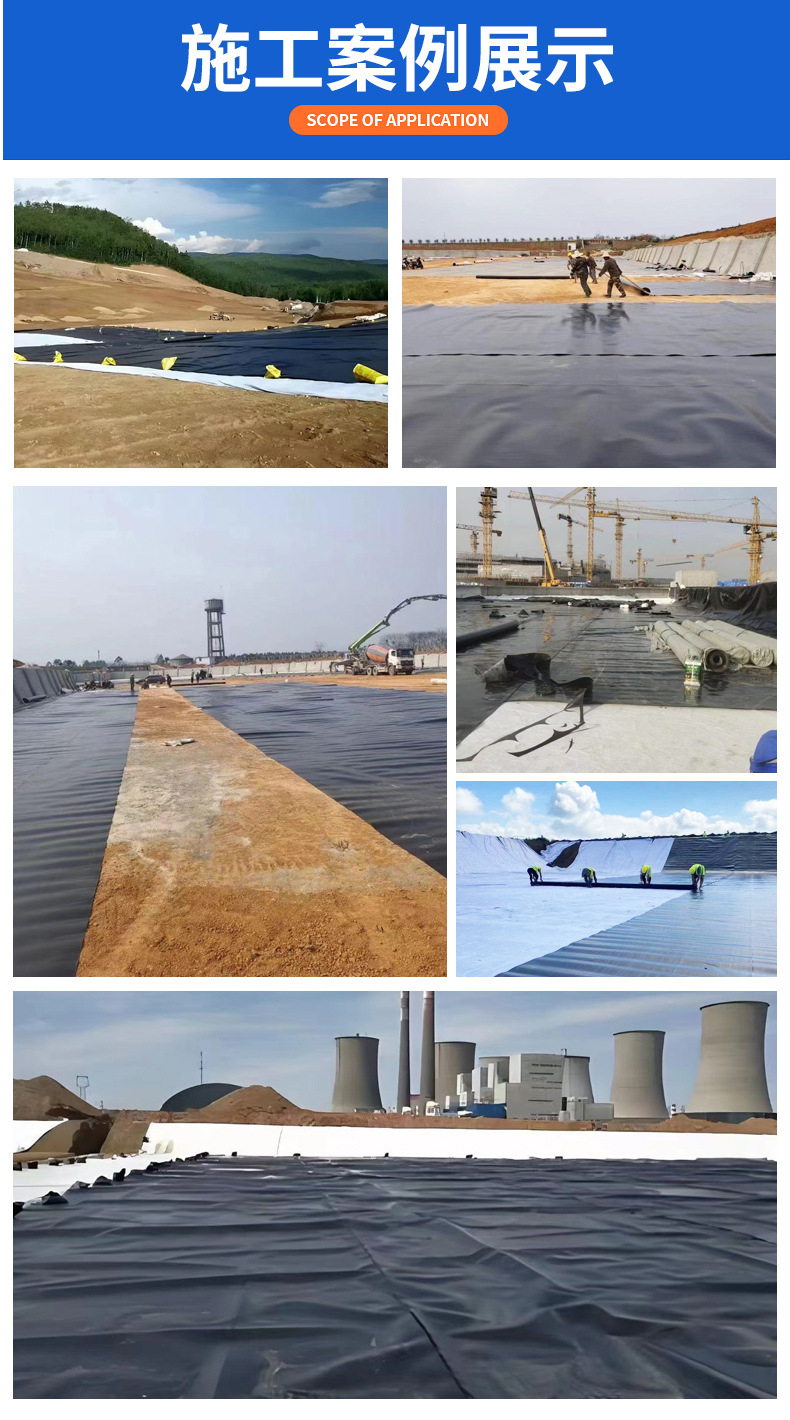

Due to its good tensile strength, high impact strength, impermeability, acid and alkali resistance, heat resistance, weather resistance, wear resistance

and other characteristics, anti-seepage geomembranes have been widely used in the construction industry in coastal areas. It is also widely used in

river embankments, reservoirs, water diversion tunnels, highways, railways, airports, underground and underwater projects. Geomembrane has become

an important material for modern national economic construction. And introduce the production technology of anti-seepage geomembrane.

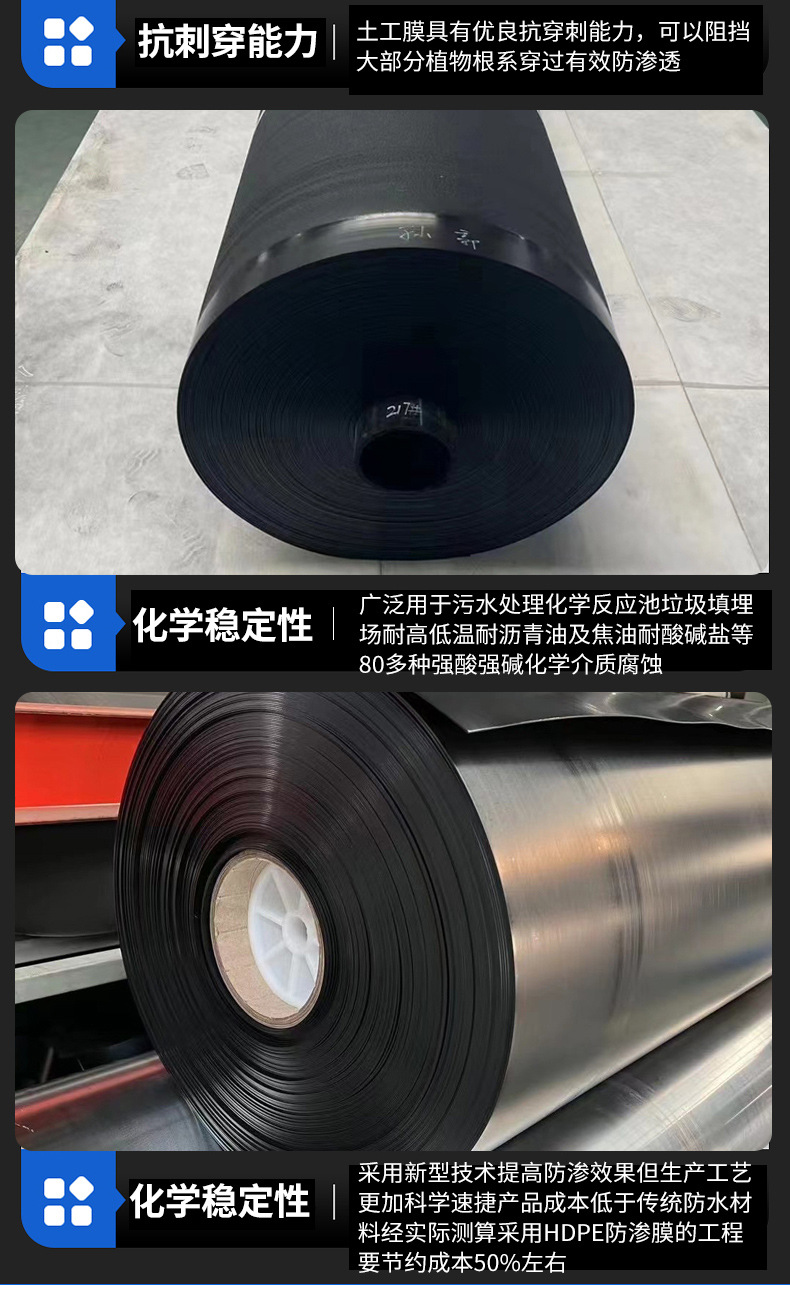

1. Chemical stability - HDPE anti-seepage film has excellent chemical stability and is widely used in sewage treatment, chemical reaction tanks, and landfills.

Resistant to high and low temperatures, asphalt, oil and tar, acid, alkali, salt and more than 80 strong acid and alkali chemical media corrosion.

2. Aging resistance - HDPE anti-seepage film has excellent anti-aging, anti ultraviolet, anti decomposition capabilities, and can be used naked. The service

life of the material can reach 50-70 years, providing a good material guarantee for environmental anti-seepage.

3. Anti plant root system - HDPE anti-seepage film has excellent puncture resistance and can resist most plant roots.

4. High mechanical strength - HDPE anti-seepage film has good mechanical strength, with a fracture tensile strength of 28MP and a fracture elongation of 700%.

5. Low cost, low efficiency, high benefits - HDPE anti-seepage membrane adopts a new technology to improve the anti-seepage effect, but the production

process is more scientific and fast, so the product cost is actually lower than traditional waterproof materials. According to actual calculations, the general

project using HDPE anti-seepage membrane can save about 50% of the cost.

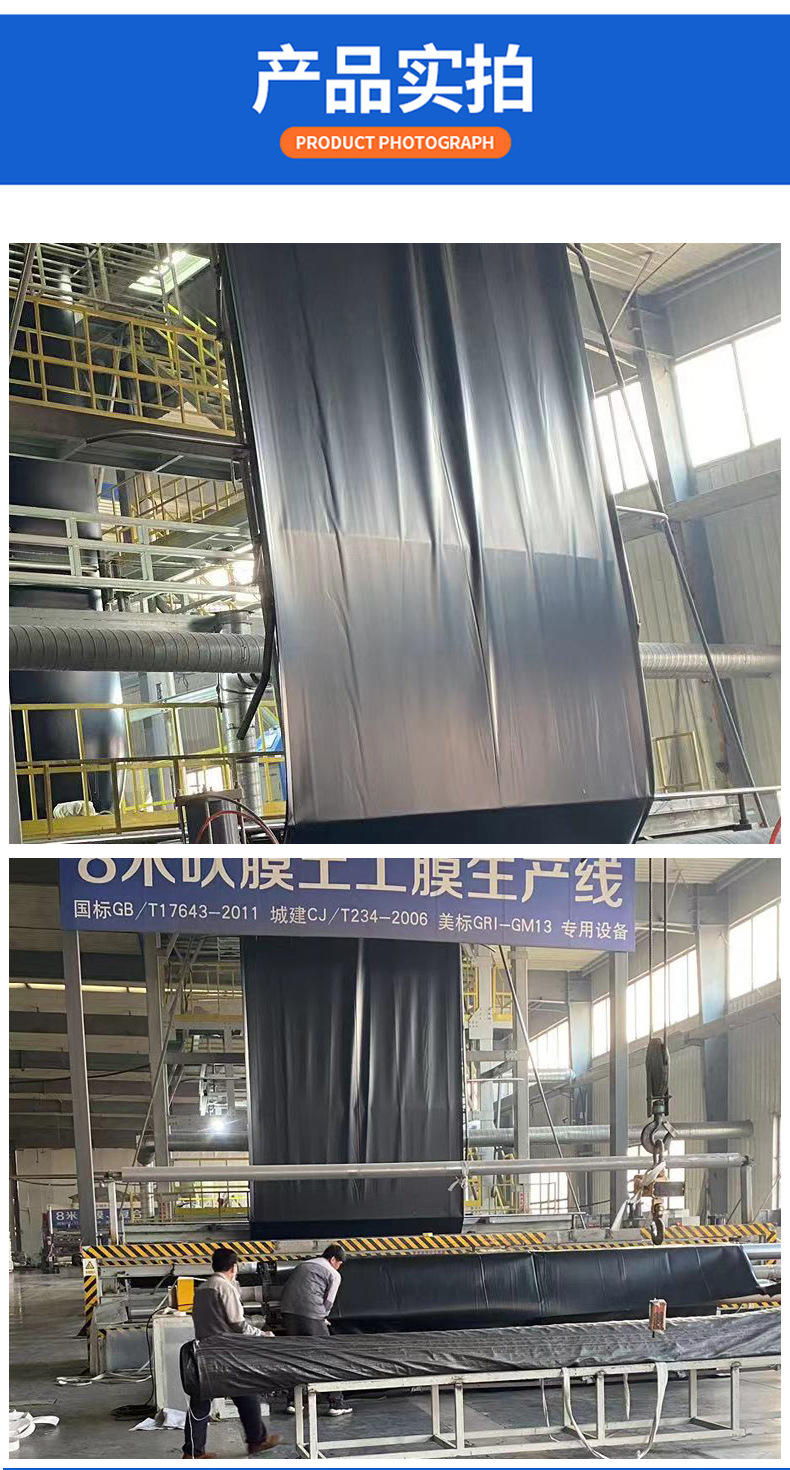

6. Fast construction speed - HDPE anti-seepage film has high flexibility, with multiple specifications and laying forms to meet the anti-seepage requirements of

different projects. It adopts hot melt welding, with high weld strength, convenient, fast and healthy construction.

7. Environmentally friendly and non-toxic - HDPE anti-seepage film is made of non-toxic and environmentally friendly materials. The anti-seepage principle is

based on ordinary physical changes and does not produce any harmful substances. It is the best choice for environmental protection, aquaculture, and drinking

water tanks.

8. Good welding effect - HDPE anti-seepage film is welded very well using a dedicated welding machine, with a weld strength greater than that of the base material

and easy to construct.

上一篇: Previous:EVA geomembrane

下一篇:Next:Geotechnical composite membrane

- 11-26The use of composite geomembrane

- 11-26Application of composite geomembrane in reservoirs

- 11-26The difference between geomembrane and composite geomembrane

- 11-26The role of impermeable membrane in aquaculture

- 11-26What is waterproof geotextile

- 11-26The function and construction method of geomembrane

- 1What is waterproof geotextile

- 2Will geomembranes pollute the environment?

- 3Classification of Geotextiles

- 4The function and construction method of geomembrane

- 5Characteristics and functions of geotextile

- 6Installation of garage roof drainage board

- 7Application of Grass proof Cloth

- 8The difference between geomembrane and composite geomembrane

- 9Key points of geomembrane welding

- 10The use of composite geomembrane

简体中文

简体中文 English

English